Byford Dolphin Accident Tragedy An Offshore Disaster

The Byford Dolphin, a semi-submersible, column-stabilised drilling rig, has carved a notable niche in the history of offshore drilling. Operated by Dolphin Drilling, a subsidiary of Fred Olsen Energy, this rig was an integral part of the oil and gas exploration activities in the North Sea. Spanning the waters of the British, Danish, and Norwegian sectors, it played a crucial role in harnessing subsea resources, particularly during its seasonal drilling operations. The rig was registered in Hamilton, Bermuda, which underscored its global operational footprint and the international nature of the offshore drilling industry.

Byford Dolphin’s journey commenced with its construction as the “Deep Sea Driller,” a pioneering model in the highly acclaimed Aker H-3 series. Designed by the Aker Group and completed at the Aker Verdal shipyard in 1974, it represented a significant advancement in drilling technology. With an impressive array of equipment and capabilities, including a maximum drilling depth of 61 kilometers and the ability to operate in water depths up to 460 meters, the rig set new standards in the industry.

However, despite its technological prowess and significant contributions, Byford Dolphin was also the site of several severe incidents, the most notorious being the 1983 explosive decompression accident which resulted in multiple fatalities. Such incidents cast shadows over its operational history and brought intense scrutiny to the rig’s safety standards and operational protocols.

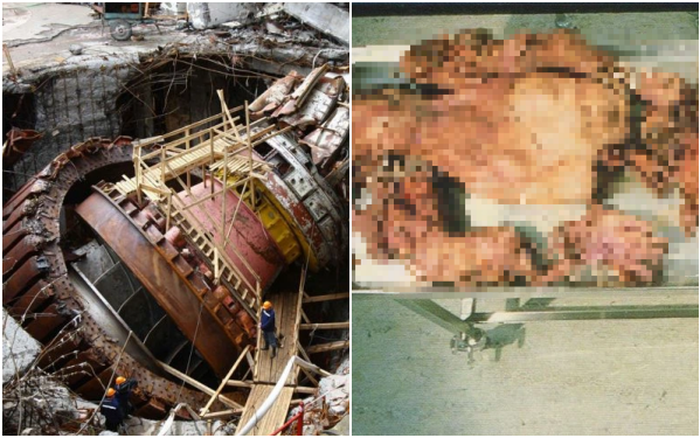

In 2019, marking the end of an era, Dolphin Drilling decided to decommission and scrap Byford Dolphin. This decision was not just the conclusion of its operational life but also a reflective moment for the industry to consider the lessons learned from its operational challenges and tragedies. The decommissioning of Byford Dolphin serves as a poignant reminder of the inherent risks in offshore drilling and the continuous need for advancements in safety and technology.

| Attribute | Details |

|---|---|

| Name | Byford Dolphin |

| Type | Semi-submersible, column-stabilised drilling rig |

| Operator | Dolphin Drilling, a subsidiary of Fred Olsen Energy |

| Areas of Operation | British, Danish, and Norwegian sectors of the North Sea |

| Registration | Hamilton, Bermuda |

| Original Name | Deep Sea Driller |

| Year Built | 1974 |

| Shipyard | Aker Verdal shipyard |

| Maximum Drilling Depth | 61 kilometers |

| Maximum Operational Water Depth | 460 meters |

| Notable Incidents | 1983 explosive decompression accident resulting in fatalities |

| Decommissioning Year | 2019 |

Contents

Overview of Byford Dolphin

The Byford Dolphin drilling rig, originally launched as the Deep Sea Driller, stands as a testament to the evolution and capabilities of offshore drilling technology. Constructed by the Aker Group and finalized at the Aker Verdal shipyard in 1974, this rig was the inaugural model in the Aker H-3 series, which would come to be recognized for its robust design and advanced technological features. The significance of the Aker H-3 series in the drilling industry cannot be overstated, as it set new benchmarks for safety, efficiency, and operational capabilities in harsh sea environments.

Technical Specifications and Capabilities

The Byford Dolphin is notable for its impressive dimensions and engineering specifications, which enabled it to handle challenging drilling operations. It measured 108.2 meters (355 feet) in length, 67.4 meters (221 feet) in breadth, and had a depth of 36.6 meters (120 feet). These dimensions made it one of the larger rigs operating in the North Sea and contributed to its stability and capacity in adverse weather conditions.

One of the rig’s most crucial capabilities was its maximum drilling depth of 61 kilometers (61,000 meters), a remarkable feature at the time of its construction. It could operate in a water depth of up to 460 meters (1,500 feet), allowing it to access deep-sea oil deposits that were previously unreachable. This capability was instrumental in expanding the boundaries of offshore oil exploration, particularly in the North Sea’s demanding conditions.

Advanced Equipment

The Byford Dolphin was equipped with several key pieces of advanced drilling equipment that enhanced its operational efficacy and safety. It featured two deck cranes, each capable of lifting 40 tonnes, which were essential for handling heavy equipment and supplies necessary for deep-sea drilling operations. The presence of a 49-meter high derrick with a Shaffer top compensator further augmented its drilling capabilities, providing the necessary infrastructure to manage the drill string and casing.

A critical component of the rig’s equipment was the blow-out preventer (BOP). The BOP on Byford Dolphin was a Hydril 476 mm (18.7 inches), capable of handling pressures up to 10,000 kPa (1,500 psi). This device was crucial for maintaining control of the well, preventing blowouts by sealing, controlling, and monitoring oil and gas wells to prevent fluids and gases from escaping into the environment.

Additionally, the rig included a Sub Sea Handling System known as the Christmas tree, a complex assembly of valves, spools, and fittings for an oil well, and a 12-point mooring system that provided stability and positioning control in the dynamic sea conditions of the North Sea.

Historical Background and Development

The initial phase of its life as the Deep Sea Driller marked the beginning of what would become a storied career in offshore drilling. The transition to the Byford Dolphin name came as it was refurbished and upgraded to meet evolving safety standards and operational requirements. Throughout its operational life, Byford Dolphin served various companies and contributed significantly to oil and gas exploration in the North Sea.

The development of the Byford Dolphin under the Aker H-3 series highlighted significant advancements in offshore drilling technology. The series introduced innovations in rig design that improved efficiency and safety, factors that were critically important given the harsh environments the rigs were designed to operate in. The Aker H-3’s impact on the industry was profound, pushing forward the capabilities of semi-submersible rigs and setting a high standard for subsequent developments.

In summary, Byford Dolphin’s design, capabilities, and the technological advancements it incorporated not only exemplified the state of the art in offshore drilling during its era but also played a crucial role in the development of the North Sea oil fields. Its legacy, marred slightly by the accidents it witnessed, nonetheless remains a significant chapter in the history of offshore exploration.

| Attribute | Details |

|---|---|

| Name | Byford Dolphin |

| Original Name | Deep Sea Driller |

| Construction | Constructed by the Aker Group, finalized at the Aker Verdal shipyard in 1974 |

| Series | Aker H-3 series |

| Dimensions | Length: 108.2 meters, Breadth: 67.4 meters, Depth: 36.6 meters |

| Maximum Drilling Depth | 61 kilometers |

| Operational Water Depth | Up to 460 meters |

| Key Equipment | Deck cranes, Shaffer top compensator, blow-out preventer (BOP), Sub Sea Handling System (Christmas tree), 12-point mooring system |

| Significance | Set benchmarks for safety, efficiency, and operational capabilities; instrumental in North Sea oil exploration |

| Legacy | Significant advancements in offshore drilling technology and impact on the development of North Sea oil fields |

Notable Incidents and Accidents

The operational history of Byford Dolphin is marked by notable incidents that had significant impacts on safety regulations in offshore drilling. These events not only highlight the inherent risks associated with deep-sea drilling but also underscore the importance of stringent safety protocols and emergency response measures.

Deep Sea Driller Accident (1976)

In March 1976, while transiting from a drilling block in the North Sea to Bergen, the rig, then known as the Deep Sea Driller, encountered severe weather conditions that led to a catastrophic grounding incident. The rig ran aground during a heavy storm, posing serious risks to both the structural integrity of the rig and the safety of the crew on board.

Outcomes

All crew members were evacuated in a timely manner, which was a testament to the emergency procedures in place. However, the evacuation was not without tragedy, as six crew members lost their lives due to accidents involving the lifeboats during the evacuation process. This incident prompted a thorough investigation into the safety equipment and emergency response strategies employed on offshore rigs.

Immediate Safety Responses

Following the accident, there were significant changes in safety protocols, particularly concerning the design and deployment of life-saving equipment. Enhancements were made to ensure that all safety gear adhered to the highest standards and that crew training for emergency situations was both rigorous and routinely updated. The incident also led to improved weather forecasting and monitoring systems on the rig to prevent similar occurrences in the future.

Diving Bell Accident (1983)

On November 5, 1983, a more devastating accident occurred on the Byford Dolphin, which resulted in the deaths of four divers and severe injuries to others. This incident involved explosive decompression and had far-reaching implications for diving safety standards.

Chronological Breakdown

The accident unfolded in the early hours while the rig was stationed in the Frigg gas field. A diving chamber system, which included two compression chambers and a diving bell, was being used for underwater operations. The divers, Edwin Arthur Coward, Roy P. Lucas, Bjørn Giæver Bergersen, and Truls Hellevik, were transitioning between the diving bell and the chambers.

The sequence of events leading to the accident began when the diving bell was reattached to the chamber system. The normal procedure required sealing the bell and chamber doors and equalizing the pressure. However, due to a tragic error, the clamp securing the bell to the chamber was prematurely released by one of the dive tenders without securing the chamber doors, causing a rapid decompression.

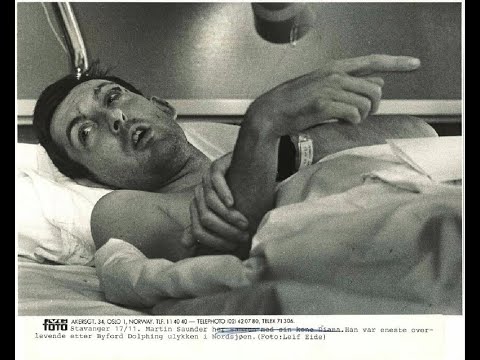

Roles and Actions

The dive tenders, William Crammond and Martin Saunders, were responsible for operating the clamps and ensuring all doors were secured. Miscommunication and perhaps a critical lapse in protocol led to the premature release of the clamp, resulting in catastrophic pressure equalization.

Medical Findings and Implications

The medical examination of the bodies revealed gruesome injuries consistent with explosive decompression. Notably, there was a significant presence of fat emboli in major arteries, the heart, and other organs, which indicated severe decompression sickness. These findings led to critical evaluations of medical standards for diving operations and spurred enhancements in decompression procedures and emergency medical readiness on drilling rigs.

These incidents on Byford Dolphin have contributed to shaping the safety protocols and technological advancements in offshore drilling operations. The lessons learned have driven changes in both national and international regulations, aiming to prevent such tragedies in the future and ensuring the well-being of the crews working in these challenging environments.

| Incident Date | Description | Consequences and Actions Taken |

|---|---|---|

| March 1976 | Ran aground during a storm while transiting from a drilling block in the North Sea to Bergen. | Evacuation led to six crew member deaths. Incident prompted a review of safety equipment and emergency response strategies, leading to enhanced safety protocols and improved weather monitoring systems. |

| November 5, 1983 | Explosive decompression accident in the Frigg gas field resulted in the deaths of four divers and severe injuries to others. | Investigation identified failures in protocol and equipment handling. Resulted in revised diving safety standards and improved decompression procedures and emergency medical readiness. |

Investigations and Legal Aftermath

The incidents involving the Byford Dolphin, particularly the tragic diving bell accident of 1983, prompted thorough investigations that unearthed a mix of human error and engineering failures. These findings catalyzed significant changes in safety regulations and equipment standards in the offshore drilling industry.

Investigation Findings

The official investigation into the diving bell accident pointed to human error as the primary cause. The dive tender who prematurely opened the clamp did so without confirmation that the other safety measures were in place. This critical lapse was compounded by engineering failures, notably the lack of fail-safe mechanisms and outboard pressure gauges that could have prevented the disaster or mitigated its severity.

Rule Changes Post-Accident

In response to the findings, several critical rule changes were implemented. The industry saw the introduction of more rigorous standards for diving equipment, including mandatory fail-safe seals and interlocking mechanisms. These rules were designed to ensure that connections between diving bells and chambers could not be disengaged while pressurized. Additionally, the incident led to broader safety audits and enhancements in training programs for rig personnel focused on emergency preparedness and equipment handling.

Allegations of a Cover-Up

The aftermath of the investigation also surfaced allegations of a cover-up by the involved parties, including equipment manufacturers and regulatory bodies. Former crew members and the Norwegian oil and petrochemical union (NOPEF) suggested that the accident report failed to address dispensations granted for critical equipment, which they believed contributed to the accident. These allegations pointed to deeper issues within the regulatory practices, sparking debates and further scrutiny.

| Aspect | Details |

|---|---|

| Incident | Diving bell accident in 1983 |

| Cause of Accident | Human error, compounded by engineering failures such as lack of fail-safe mechanisms and pressure gauges. |

| Changes Implemented | Introduction of more rigorous standards for diving equipment, mandatory fail-safe seals, and interlocking mechanisms. |

| Training Enhancements | Enhanced training programs for rig personnel on emergency preparedness and equipment handling. |

| Allegations Aftermath | Allegations of a cover-up by equipment manufacturers and regulatory bodies. Sparked debates and scrutiny over regulatory practices. |

Legacy and Impact

Despite its operational challenges and associated tragedies, Byford Dolphin significantly influenced safety standards and practices within the offshore drilling industry.

Influence on Industry Safety Standards

The accidents aboard Byford Dolphin were pivotal in shaping the regulatory landscape of offshore operations. The rig’s experiences underscored the necessity for stringent safety protocols and the continuous updating of equipment and training. The industry-wide shift towards more comprehensive safety measures can be directly traced back to these incidents, which highlighted the potential cost of negligence and inadequate safety measures.

Lawsuit by the North Sea Divers Alliance

The North Sea Divers Alliance, representing divers and their families, pursued legal action against the Norwegian government and other entities, alleging negligence and unsafe working conditions. In 2008, they obtained a report that substantiated claims of faulty equipment contributing to the accident. This lawsuit culminated in the divers’ families receiving compensation, acknowledging the mishaps and their profound impact on the victims’ lives.

Reflection on Other Incidents

Another incident in 2002, where a worker was fatally injured by a falling object, further tainted the rig’s safety record. This accident resulted in Byford Dolphin losing a significant contract with Statoil, which cited concerns over the rig’s safety practices. The financial and reputational damage from this incident reinforced the importance of maintaining rigorous safety standards to prevent operational and financial setbacks.

In conclusion, Byford Dolphin’s legacy is twofold: it stands as a reminder of the risks inherent in offshore drilling and as a catalyst for transformative safety improvements in the industry. The rigorous standards and practices that emerged from its operational history continue to influence global offshore drilling operations, aiming to safeguard the lives of those who brave the challenging conditions of deep-sea oil and gas exploration.

| Aspect | Details |

|---|---|

| Influence on Safety Standards | Significantly influenced safety protocols in the offshore drilling industry, leading to a shift towards more comprehensive safety measures. |

| Legal Actions | The North Sea Divers Alliance took legal action against the Norwegian government and other entities for negligence and unsafe working conditions, leading to compensation for divers’ families in 2008. |

| 2002 Incident | A worker was fatally injured by a falling object, causing Byford Dolphin to lose a significant contract with Statoil over safety concerns. |

| Legacy and Conclusion | The rig’s legacy includes being a catalyst for transformative safety improvements in the industry and serving as a reminder of the risks in offshore drilling. |

The operational history of the Byford Dolphin, marked by both technological triumphs and tragic accidents, encapsulates the complex narrative of offshore drilling. As a pioneering semi-submersible rig, Byford Dolphin introduced groundbreaking capabilities to the oil and gas industry, significantly advancing the exploration and extraction of undersea resources. Its construction as the first in the Aker H-3 series set a new benchmark in rig design and functionality, allowing access to deeper and more challenging marine environments.

However, the rig’s legacy is also deeply intertwined with the critical safety lessons learned from its incidents. The 1983 diving bell accident, in particular, was a stark reminder of the potential human costs of inadequate safety measures and equipment failures. This tragedy spurred a series of investigations that highlighted significant shortcomings in operational protocols and emergency response mechanisms, leading to sweeping reforms in safety regulations across the offshore drilling industry.

These reforms included the implementation of more stringent safety standards, such as the introduction of fail-safe seals and interlocking mechanisms for diving systems, and enhanced training for emergency situations. Such changes have undeniably shaped current practices, shifting the industry’s focus toward an increasingly safety-conscious approach. The emphasis on rigorous safety protocols and continuous improvement in safety equipment now serves as a fundamental principle in offshore operations.

Reflecting on the Byford Dolphin’s history offers vital insights into the dynamic interplay between technological innovation and safety in offshore drilling. The lessons drawn from its operational life continue to influence modern safety practices, ensuring that the pursuit of natural resources does not come at the expense of human lives. This ongoing legacy underscores the importance of vigilance, responsibility, and innovation in navigating the challenges of offshore drilling.

Technical Specifications of Byford Dolphin

- Type: Semi-submersible, column-stabilised drilling rig

- Built by: Aker Group at Aker Verdal shipyard

- Year Built: 1974

- Overall Length: 108.2 meters (355 feet)

- Breadth: 67.4 meters (221 feet)

- Depth: 36.6 meters (120 feet)

- Maximum Drilling Depth: 61 kilometers (61,000 meters)

- Operating Water Depth: Maximum 460 meters (1,500 feet)

- Derrick: 49 meters (160 feet) with a Shaffer top compensator

- Mooring System: 12-point

- Blow-Out Preventer: Hydril 476 mm (18.7 inches), 10,000 kPa (1,500 psi)

- Sub Sea Handling System: Christmas tree

- Deck Cranes: 2 × 40 tonnes

- Crew Quarters: Accommodation for 102 persons

- Operating Deck Load: 3,025 tonne

Diagrams and Technical Drawings

- Rig Layout: Illustration detailing the overall structure and compartments of the Byford Dolphin, including the drilling deck, living quarters, and engine rooms.

- Safety Systems Diagram: A schematic showing the arrangement of safety equipment, including the blow-out preventer and the mooring system.

- 1983 Accident Scene Diagram: Detailed diagrams depicting the setup of the diving bell and decompression chambers, illustrating the connections and sequence of events leading to the explosive decompression incident.

- Sub Sea Handling System Diagram: Visual representation of the Christmas tree configuration and its components used in subsea operations.

References

- “Byford Dolphin Rig Specifications.” Dolphin Drilling. Official specifications and historical data on the Byford Dolphin.

- “Investigation Report: 1983 Diving Bell Accident.” Safety and Regulatory Authority. Detailed analysis of the causes and consequences of the 1983 accident.

- “Deep Sea Driller Incident, 1976: A Case Study.” Journal of Offshore Mechanics and Arctic Engineering. An academic review of the 1976 grounding incident.

- “Evolution of Safety Regulations in Offshore Drilling.” International Journal of Petroleum Engineering. A scholarly article discussing the impact of major accidents, including those on the Byford Dolphin, on safety regulations in the industry.

- “Historical Review of Aker H-3 Series Rigs.” Marine Engineering History Series. Provides a background on the design and development of the Aker H-3 series, highlighting the Byford Dolphin.

- “Norwegian Petroleum Directorate: Safety Updates Post-Byford Dolphin.” Government reports on regulatory changes following the accidents on the rig.

- “North Sea Divers Alliance: Legal Documentation.” Archive of legal proceedings and outcomes related to the lawsuits filed by the North Sea Divers Alliance.

- “Technical Analysis of Offshore Drilling Equipment Failures.” Technical journal that includes case studies on equipment like blow-out preventers and their operational failures.

Unlock the Keys to Success Elite Employees Original Video

Freddie Gibbs Leaked Exposed Unfiltered and Uncensored

Exposé on the Controversial Mostlycryin Leaked Video

Pretty Nicole Trending Video Today internet by Storm

Travis Kelce Sister Leaked Video Causes Controversy

Little Melita Viral Video An Inspiring Tale of Resilience

Adin Ross Leaked Video A Lesson in Personal Privacy Invasion